News

High-Purity Sugar Beet Syrup at Tereos France

Tereos Sugar France has redesigned its industrial tools to better align with market and customer demands. We are talking about “flexibility” in the business. One of its core element is the production of syrup. It is made during harvest periods, stored and then processed into a variety of products as needed.

An Elite Syrup!

What we mean here is a high-purity syrup (HPS). HPS is produced in sugar beet harvest season—from October to January—and this is an essential step in the beet sugar extraction process. During this time, plants are working non-stop so they are ready to receive sugar beets on time. The plants are aiming to process the sugar beets before they spoil or are exposed to frost, at the risk of losing their sugar content. However, plants do face a barrie: despite their large intake capacity, plants cannot crystallize everything they receive. The solution? Store some of the High-Purity Syrup:

What we mean here is a high-purity syrup (HPS). HPS is produced in sugar beet harvest season—from October to January—and this is an essential step in the beet sugar extraction process. During this time, plants are working non-stop so they are ready to receive sugar beets on time. The plants are aiming to process the sugar beets before they spoil or are exposed to frost, at the risk of losing their sugar content. However, plants do face a barrie: despite their large intake capacity, plants cannot crystallize everything they receive. The solution? Store some of the High-Purity Syrup:

One Syrup, Four Uses

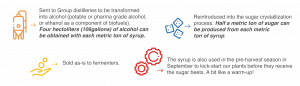

Some of the HPS obtained is then stored in tanks so it can be processed between harvests, from February through September. It can then meet four major needs; it can be:

The syrup is also used in the pre-harvest season in September to kick-start our plants before they receive the sugar beets. A bit like a warm-up!

Syrup as an Essential Ingredient in a Volatile Market

HPS production is therefore part of an arbitration logic to which Tereos France must lend itself, and which is fully in line with the flexibility of our industrial tool.

Even before the harvests take place, Tereos France is under contract for an annual tonnage of sugar with its customers. This year, for example, the harvest was affected by yellow beet virus and climate hazards: the need to produce crystallized sugar is strategic and helps to meet these contracts. To do this, the HPS is reintroduced as a priority into the crystallization process and only a small amount is redirected to the distilleries to become alcohol.

This ability to adapt has required adjustments and investment. Firstly, in three plants, additional equipment was installed in order to reduce the sugar content of the final syrup until molasses are obtained. At the same time, the Group invested in new storage space for HPS at three plants.